Our Products

PEXOWELL plastic doctor blade has excellent characteristics such as non-metallic particles, ultra-long service life, excellent chemical resistance, environmental protection, safety, high economic benefits, etc. It is widely used in new energy, electronics, medicine, optical and traditional printing industry. You can buy PEXOWELL standard doctor blade with excellent performance. Or at the same time, we also provide customized plastic blades development services for customers’ unique needs. No matter what your application requirements are, ZONAPEX will provide you with solutions with many years of product development and a deep understanding of engineering plastics.

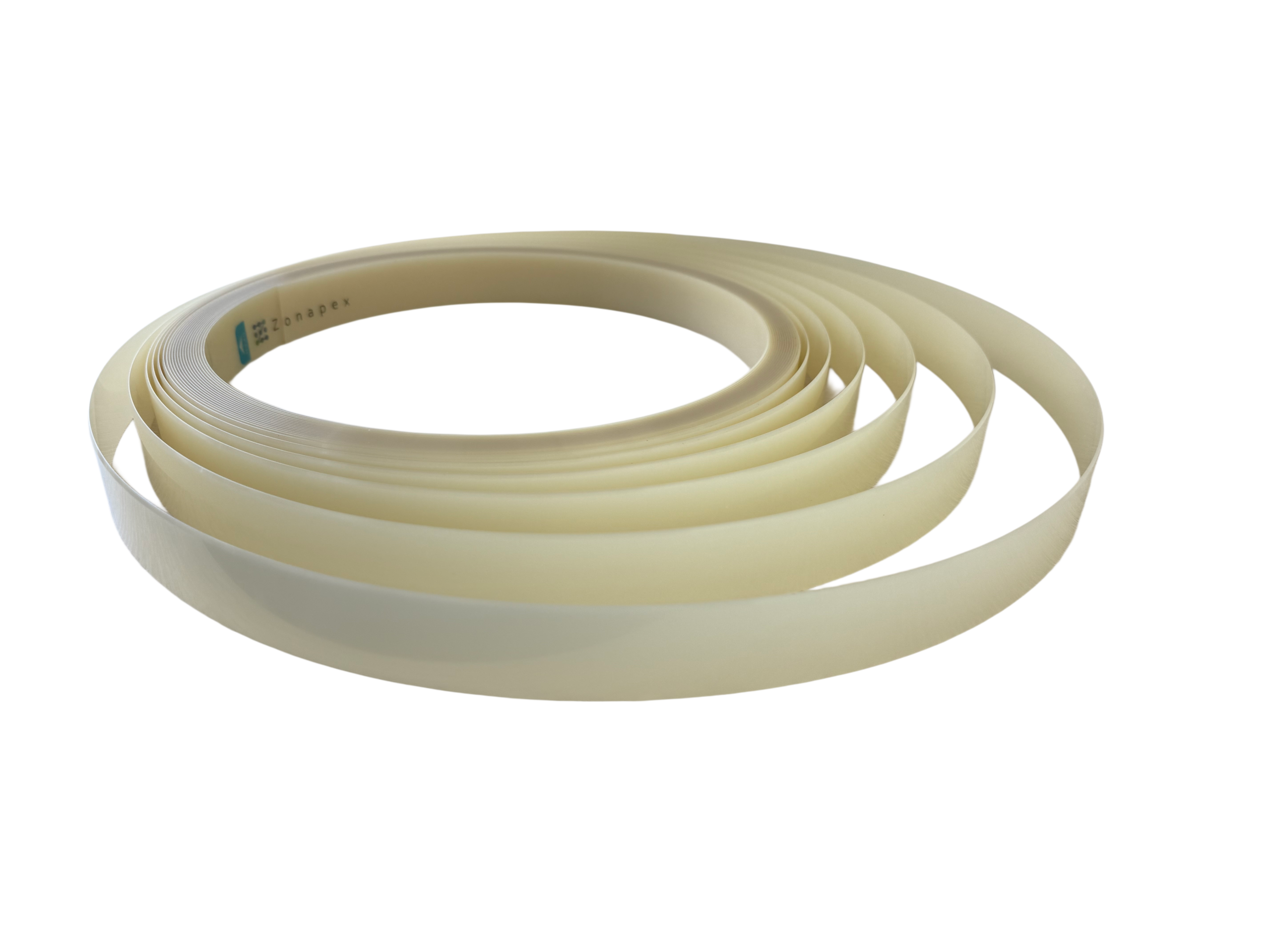

PEXO

A - Series

PEXOWELL A series plastic scrapers are made from Zonapex’s developed Polyamide blades, which stand out for their excellent strength and toughness. At the same time, their wear resistance also exceeds that of traditional ordinary nylon blades. We have innovated the blade material, greatly improving its waterproof performance and enhancing its working stability in various environments. With its excellent performance in the production process of new energy batteries and functional films materials, this product has won wide acclaim from customers and is an absolute pioneer in nylon doctor blades.

- New energy, battery and electronic

- Separator film

- Coating and laminating

- Corrugated printing (high quality, high speed)

- Specialty application

Stiffness

Toughness

Metering

Wearing Resistance

Maxi Width

80mm / 3.149"

Thickness

1.0, 1.2, 1.5mm / 0.039, 0.047, 0.059”

Profile

13, 22, 30, 45, 90°, Lamella

Length

30m / 98’

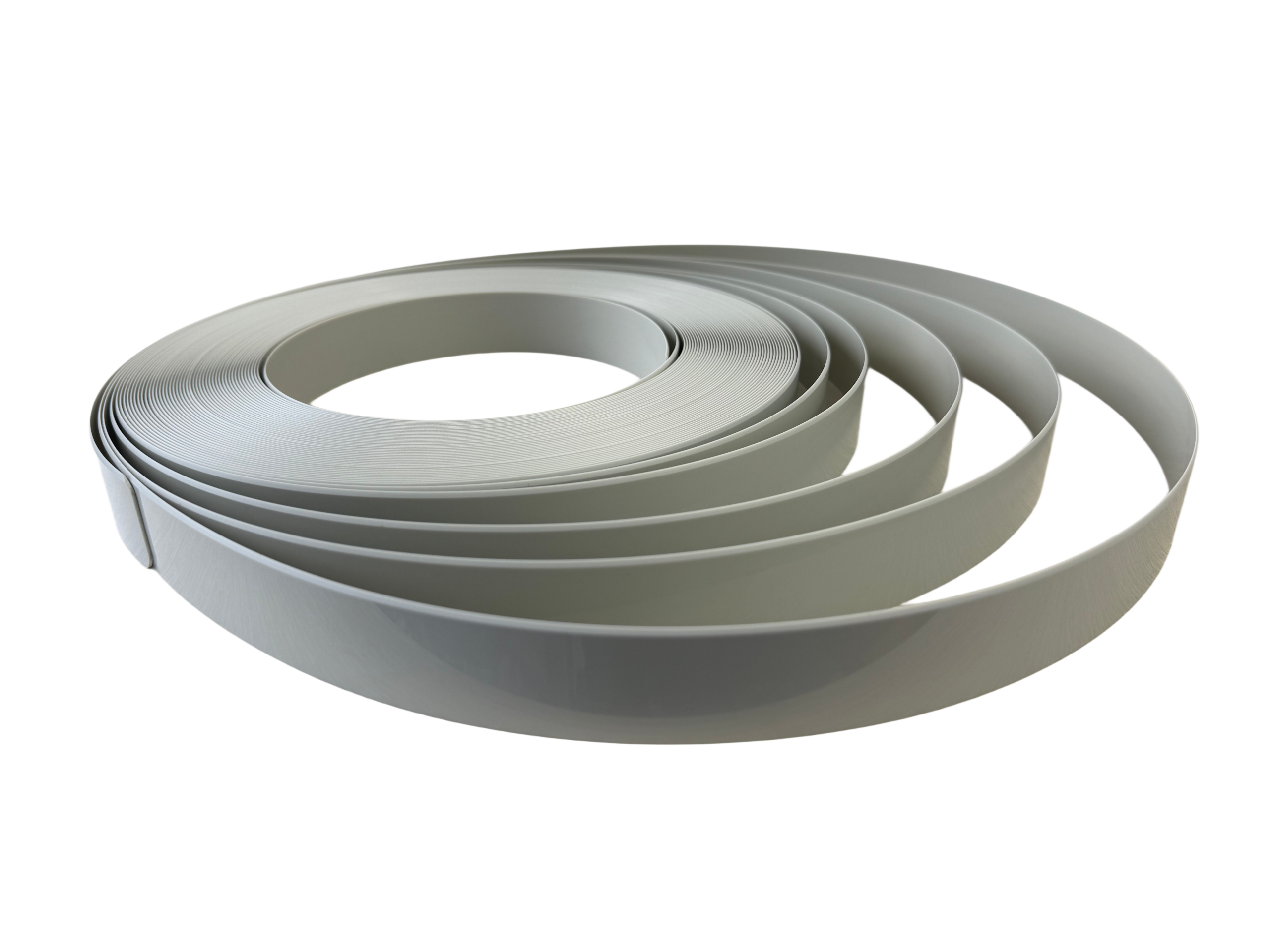

PEXO

E - Series

PEXOWELL E series doctor blades and sealing blades are designed for long-lasting durability. We offer blades of various specifications. With many years of experience in engineering plastic applications, we are the only blades manufacturer on the market that can provide 1.2 mm thick strong polyester doctor balde. We have made up for the shortcomings of PET’s weak toughness by modifying the material, so that it can be used in more scenarios. Its life span has a very obvious advantage over steel scrapers.

- New energy, battery and electronic

- Separator film

- Coating and laminating

- Wide Web Printing

- Flexography printing

- Gravure printing

Stiffness

Toughness

Metering

Wearing Resistance

Maxi Width

80mm / 3.149"

Thickness

0.2, 0.35, 0.5, 0.8, 1.0, 1.2mm / 0.008, 0.014, 0.020, 0.032, 0.039, 0.047”

Profile

13, 22, 30, 45, 90°, Lamella

Length

30, 70, 100m / 98, 230, 328.1’

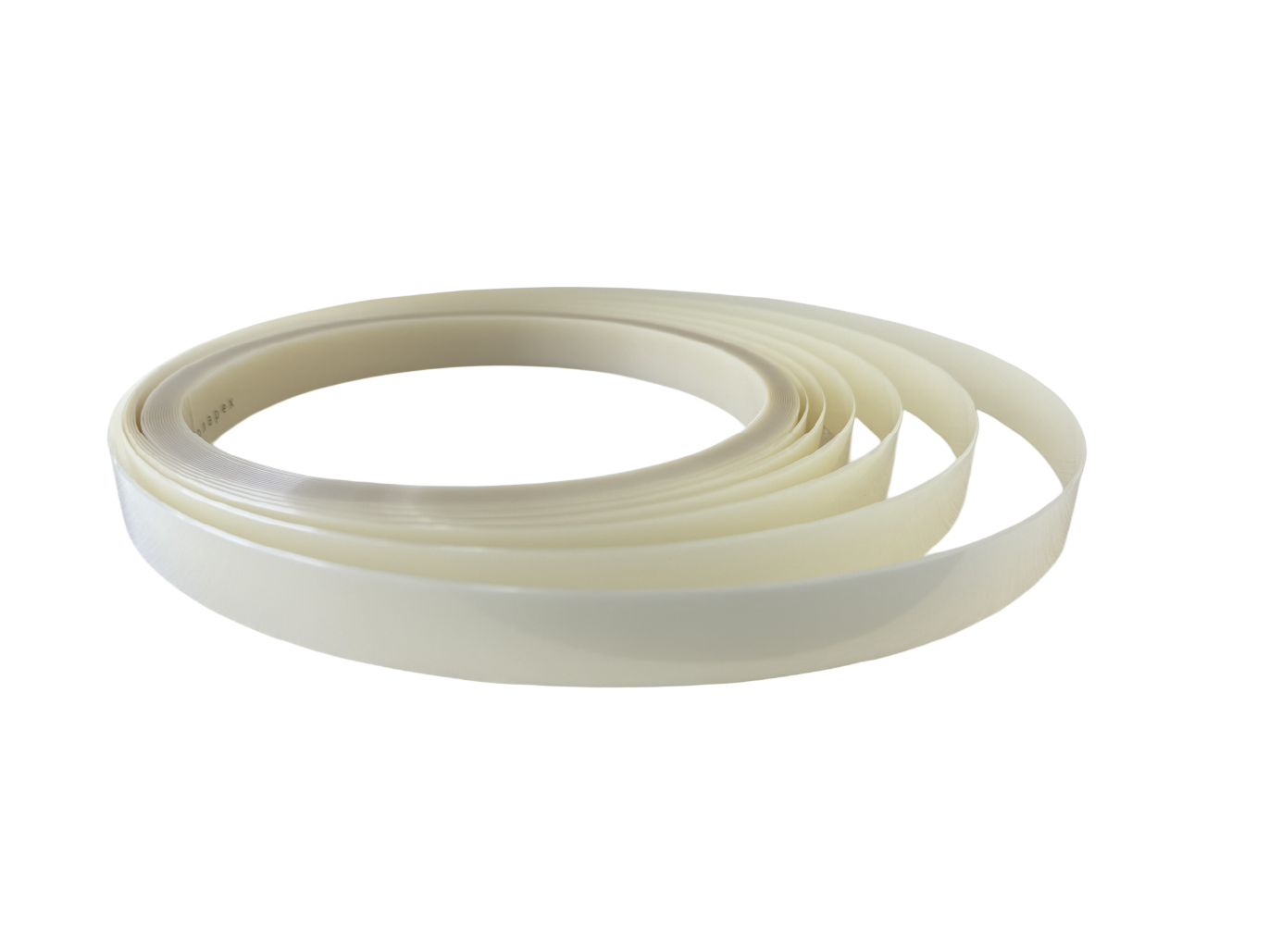

PEXO

K - Series

PEXOWELL K series is made of newly developed cutting-edge materials, with ultra-high wear and impact resistance, excellent chemical stability, low friction and self-lubrication. These characteristics ensure accurate ink scraping and long service life, making it an ideal choice for high-end coating, optical film, medical kits and other high-demand coating and printing applications.

- New energy, battery and electronic

- Separator and optical film

- Precision coating and laminating

- Specialty application

Stiffness

Toughness

Metering

Wearing Resistance

Maxi Width

80mm / 3.149"

Thickness

1.0, 1.2mm / 0.039, 0.047”

Profile

13, 22, 30, 45, 60, 90°, Lamella

Length

30m / 98’

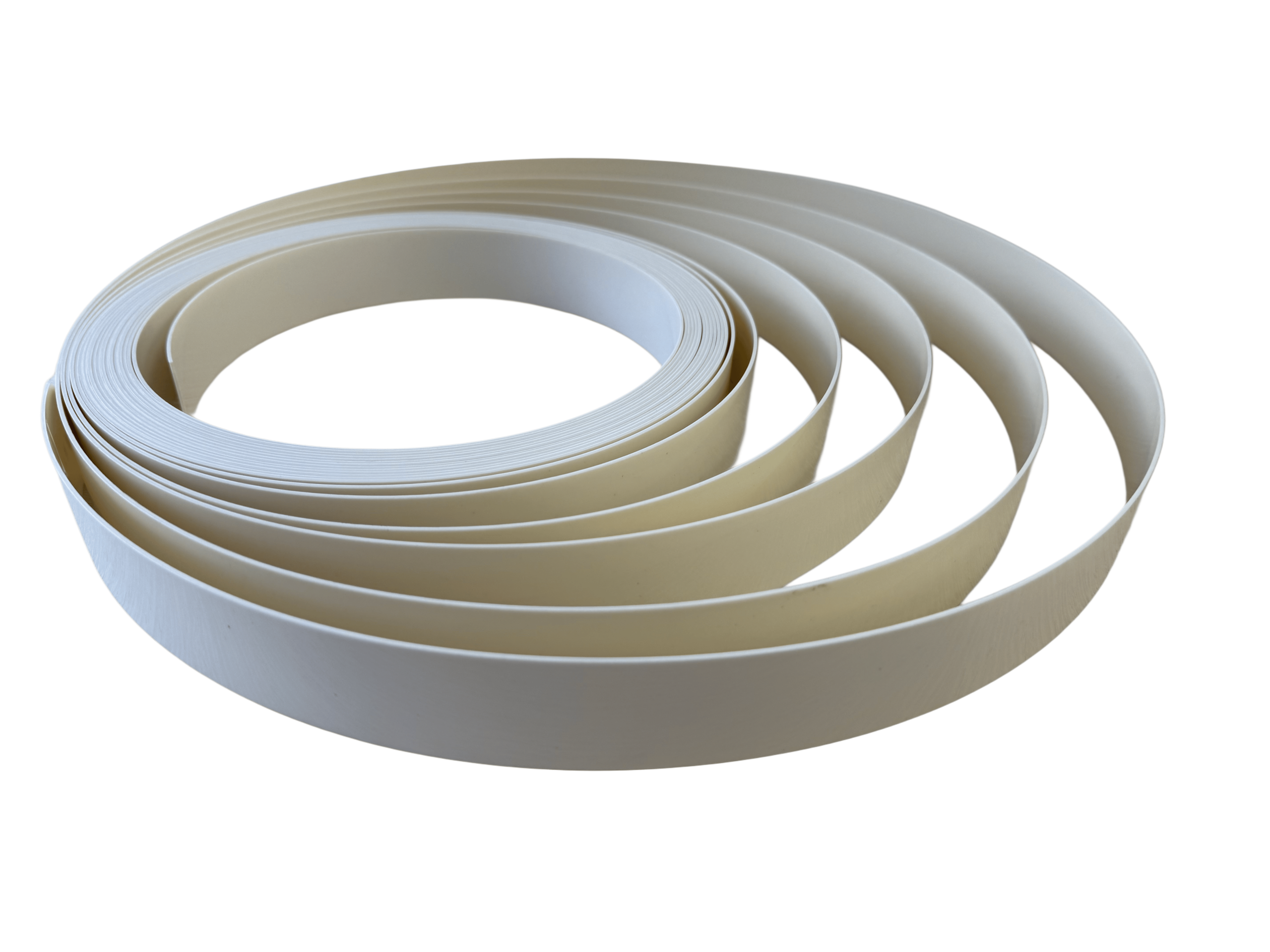

PEXO

P - Series

PEXOWELL P series doctor blade uses UHMWPE, a high-performance engineering plastic that has long been widely used in the printing industry that requires high durability and low friction for its excellent wear resistance and toughness. UHMWPE’s wear resistance far exceeds that of ordinary plastics, and it can be used for a long time under high load and high-speed operation environments with almost no wear. Its excellent toughness enables UHMWPE to maintain stability during high-speed operation, avoiding problems such as scraper breakage.

- Coating and laminating

- Flexography printing

- Gravure printing

- Corrugated printing